As we mentioned in an earlier post on green coffee, the coffee industry uses common terms that make sense to those within the industry, but when we think about them, these terms can actually be really confusing. Coffee “processing” is another one of those terms. We hear about “processed foods” as being bad for our health, because they have additives and extra ingredients; however, processed coffee has an entirely different meaning.

What does it mean to "process" coffee?

When coffee is harvested, in order to transform it into the beverage we know and love, it must begin to be processed soon afterward—within about 12-24 hours, depending on the temperature and weather. If it is hot and raining, the cherries will start to rot in a few hours, so choosing a processing method that protects the green coffee is a primary concern for producers. When we take the harvested coffee fruit, remove the parts we don’t want, and end up with just the coffee beans without parchment, we can say we have processed the coffee.

There are actually two key stages of processing, which are fruit removal and parchment removal.

Sometimes this happens simultaneously, sometimes it is two different steps. At some point along with the fruit and parchment removal is the critical step of drying the coffee, which many consider being the most important and impactful aspect of processing. The coffee needs to be dried to about 12% moisture content (and below 0.70aw water activity) before it can be bagged and shipped. This moisture level is for food safety reasons to prevent microorganisms from forming.

The main processing types have suggestive names, ranging from “fully washed” to “pulped natural” (and “semi-washed”) to “full naturals”, and there are dozens of variations in between, all of which impact the taste and health aspects of the finished green coffee. Most conventional producers choose a certain processing method for practical reasons, rather than for sensory enrichment. For example, producers in Yemen generally do not have the vast quantities of water needed for the washed coffee method.

Specialty coffee producers, who are focused on quality and clear or unique sensory characteristics of their coffees, tend to experiment with different methods that bring out distinctive, desirable attributes of their coffees-- that’s some of what makes specialty coffee special. These methods need attention and equipment for which many producers either don’t have the infrastructure, employees, or money to accomplish, or they simply don’t want to complicate things.

The majority of the coffee in the world is not specialty grade, though. During the course of growing, harvesting, and processing coffee any number of issues may arise that cause defects in green coffee that impact its quality and health. Keeping the number of defects to as low a count as possible is critical for the sale of the coffee, because defects, characteristics, and overall quality of the coffee will determine the price. High standards like those seen in chemical free coffee emphasize why careful processing is so important to both safety and taste.

Now, onto more detail about processing... For starters, the 2 primary methods of processing coffee are natural ("dry method") and washed ("wet method").

Natural Coffee Processing

(aka: dry processing, unwashed, dry method, dried-in-cherry, sun-dried, cherry-dried, and fruit dried)

Natural processing requires the least amount of equipment and the fewest steps. The coffees are dried in cherry form, then hulled and milled for grading and bagging.

The coffee in the photo below is being dried on an “African raised bed” using the natural processing method.

The bed has a wooden frame with a screen on the bottom, so that the coffee can dry more evenly. This shows high-quality, well-picked coffee that so far is being dried properly.

Natural processed coffees are often dried on patios, where they are continually turned to ensure even drying.

Raised bed coffees are turned regularly, too, as they lay on screens that allow airflow both from underneath and above.

As the coffee dries, it looks like big raisins, but unlike raisins, the outside skin of the coffee becomes a hard shell. When the time arrives to get the green coffee out, the skin and parchment at this stage are fused together from the sugar in the fruit that has dried, and both come off during hulling.

The photo above shows a well cared for and likely healthy coffee. The coffee is clean and is drying evenly with good airflow to prevent mold growth or rotting.

Close-up of a dried coffee fruit.

Below is a photo of coffee cherries that are of various stages of ripeness and are not being dried properly—you can see they have begun to get moldy, which is exactly what can lead to health problems like mycotoxin contamination.

Washed Coffee Processing

(aka: washed arabica, fully washed, wet method, wet-milled, parchment dried; also "washed milds" for Central and South American arabicas; also, “double-washed” if additional water is used to soak beans after fermentation)

Washed coffees are pulped and then fermented at a wet mill to remove the mesocarp layer (the mucilage and pectin) before being dried and sent to be hulled and graded at the dry mill. There are many different types of pulpers—below is a disk pulper that rubs the skin off the seeds.

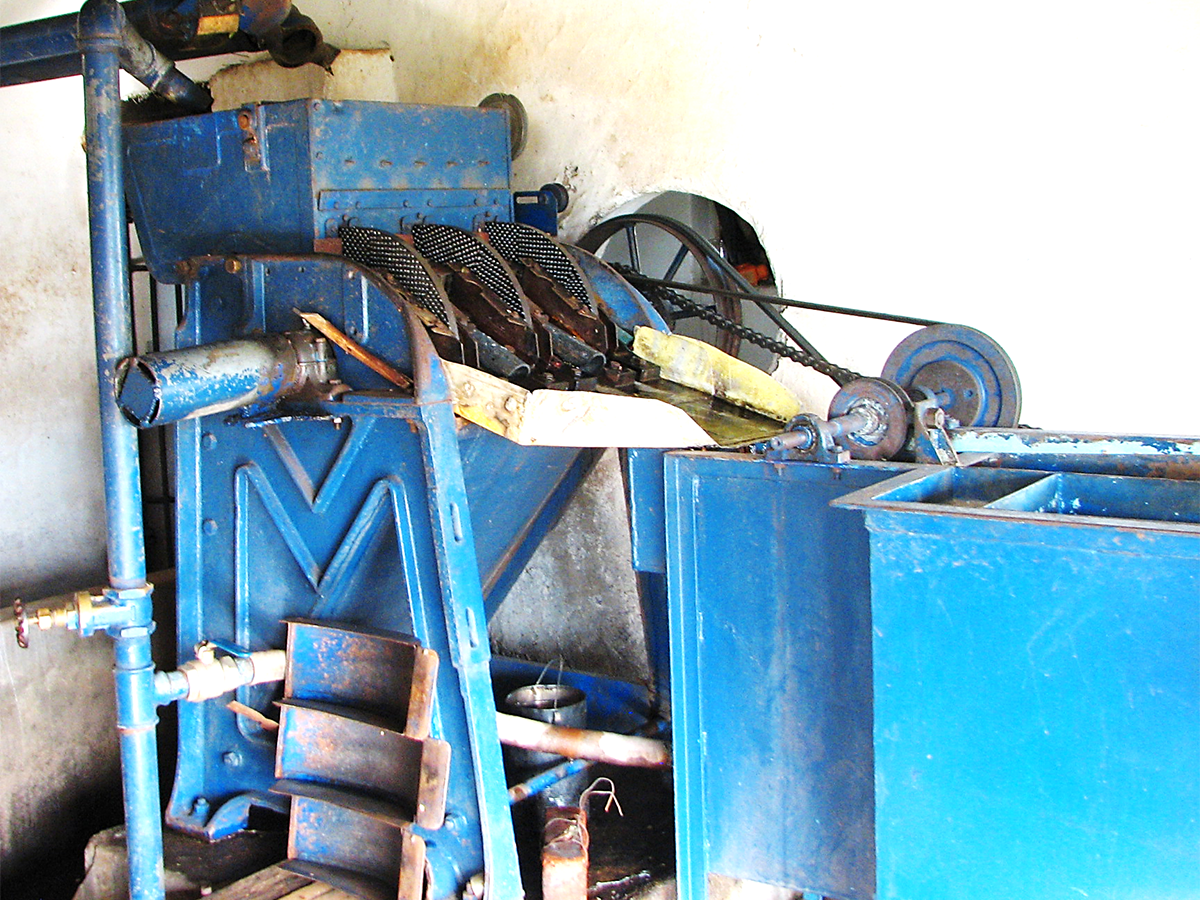

Below is a drum pulper.

There are variations in fermentation that can impact the coffee flavor and quality. Fermentation involves microbes, which consume the sugars and break down the mucilage coating the parchment. After about 12-48 hours (depending on a number of factors), the coffee is released from the fermentation tanks into some type of washing channel (photo below) that helps scrub off the final mucilage and cleans the coffee.

Sometimes mechanical demucilaging machines are used (photo below).

From there the coffee is sent to dry in its parchment (photo below), and when it reaches about 12% moisture it is sent to the dry mill for hulling, grading, and bagging.

How do these processing methods impact the health of the coffee? There are various theories, and hundreds of different types of coffee have been used by scientists, when they are studying “coffee and health” (and often the research does not state which types). It is difficult to make even general statements about processing methods and health because there are numerous variables involved in the development and processing of coffee. However, attention to detail at every stage supports the goal of healthy acrylamide free coffee for consumers.

However, there are some key practices for healthy processing:

The coffee must begin to be processed as soon as possible and within 12 hours of picking to avoid the coffee from rotting, developing mold and mycotoxins, and over-fermenting.

Water must be clean and free of contaminants. Surfaces need to be cleaned often to avoid the buildup of microorganisms, and coffee needs to be dried properly at the right temperatures.

Afterward, coffee needs to be stored, graded, and bagged correctly and at the right moisture and water activity levels.

Hopefully, this introduction to coffee processing has demystified what it means to "process" coffee. If you have any questions or comments, we’d love to hear from you. Drop a message in the comments below.

In our next blog, we’ll dive into what it means to “honey-process” coffee (hint: the honey-processing method is probably not what you think.)

9 comments

I just learned about your coffee. It interests me and I will get some soon. It looks like you don’t have to roast your coffee. Am I correct?

Does it come in already ground?

Thanks

———

Purity Coffee replied:

Hi Angie! We are so happy you found us! Our coffee is already roasted and is available in whole beans, coffee pods, and sachets. Feel free to reach out if you have any questions about our coffee.

Always enjoy your informative posts. Looking forward to the next post to learn how Purity does “process” their coffee.

Thank you for the info. I stayed away from coffee for years because it went through me 15 minutes later. No such problem with yours.

I really learned a lot!

So…………..How does Purity “process” its coffee?

You left us hanging!!!😎

———

Purity Coffee replied:

Stay tuned for our next post! 😉

Leave a comment